Industrial HVAC System (Heating, Ventilation, Air Conditioning)

- Fan Industrial Fan Solution Achieving Maximum Efficiency through Innovative Airflow Control Technology

-

The Air Foil Fan features an airfoil shape inspired by aircraft wings, providing the highest efficiency among centrifugal blowers, with low noise and high-speed rotation.

Its smaller impeller diameter allows for overall size reduction. The impeller is constructed with 11 blades, each welded onto the hub and side plates. The blades are relatively broad, made by bending steel plates into an airfoil shape. Our industrial fans employ airflow stabilization guide vanes to minimize collisions of airflow at the impeller edges, maximizing efficiency.

-

Key Functions

-

- 3% efficiency improvement, 2dB noise reduction, 7% increase in static pressure

- Minimizes equipment transportation and installation space

- Easy to replace, durable structure

-

Applications

-

-

Construction

and Engineering

Projects -

Large Buildings

-

Industrial Use

-

-

Core Advantages

-

-

- Reduced turbulence by applying airflow stabilization guide vanes

-

- World’s highest efficiency

-

- AMCA performance and noise certification

-

-

- Achieving World-Class Efficiency with Innovative Technology

-

Applying our patented airflow stabilization guide vane reduces turbulence that could interfere with equipment operation, achieving the world’s highest efficiency.

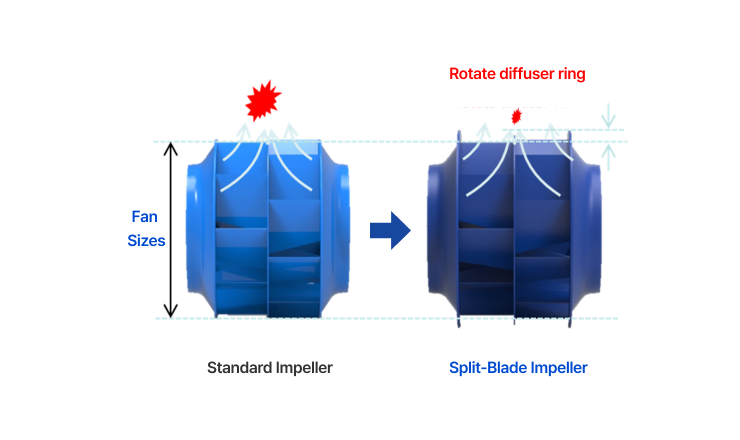

By adopting a Partial Impeller (split-blade impeller) that reduces energy consumption during power transmission, a segmented casing structure that enhances durability, and a pull-out structure for easy maintenance, our fans improve performance with a 3% increase in efficiency, a 2dB(A) noise reduction, and a 7% increase in static pressure.

-

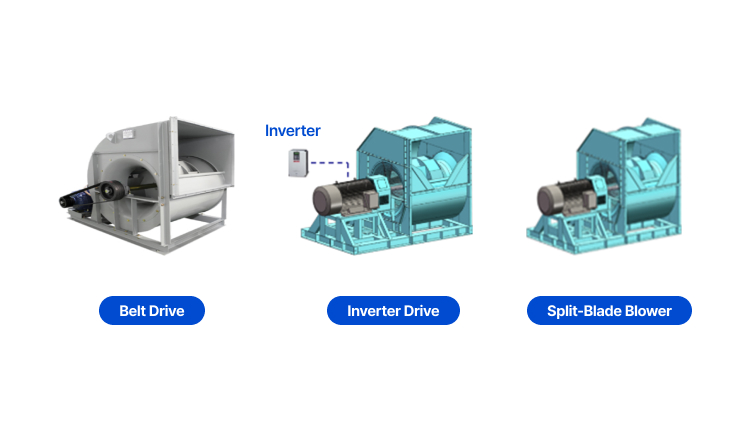

- Development of the World’s First Dual-Inlet Split-Blade Blower

- We developed the world’s first dual-inlet split-blade blower. While most HVAC blowers use belts and pulleys to transmit power, our dual-inlet split-blade blower adopts a direct-drive method without belts and has pioneered technology to operate without an inverter, leading the industry.

-

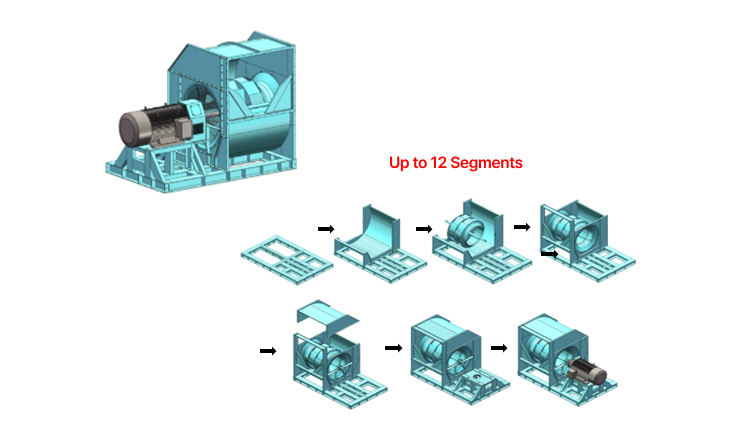

- Casing Divisible into 12 Segments for Assembly

- Unlike competing products with welded structures, our industrial fan casing can be divided and assembled into up to 12 segments. This design not only increases durability but also facilitates easy on-site transport, making it a basic specification for high-tech facilities.

-

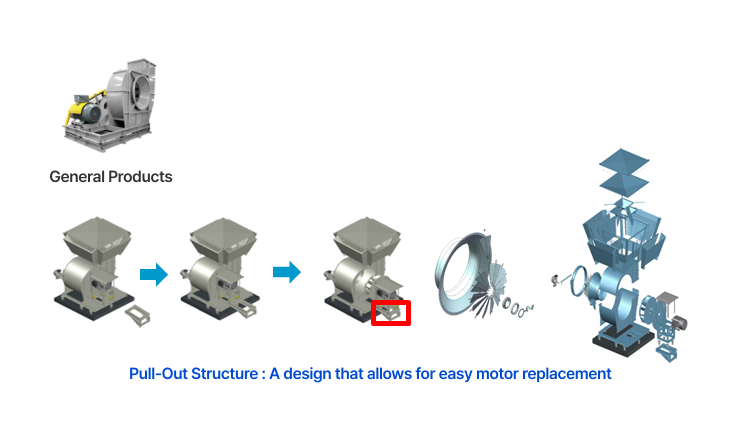

- Pull-Out Structure for Maintenance without Special Tools

-

Exhaust fans with casing typically make it challenging to disassemble the motor for maintenance.

We developed a pull-out product with specialized casing and motor bases, allowing maintenance without special tools.