- AUTO BENDING We produce tube and piping products for the high-tech industry using advanced materials and precise engineering.

-

With the latest CAD/CAM technology, we enhance design precision and maximize production efficiency through advanced automation and robotics. Real-time data monitoring ensures continuous quality control, minimizing defect rates. This integration of advanced technology guarantees consistent quality and accuracy, even in large-scale production.

To meet stringent high-tech industry requirements, we continuously invest in research and technology development, securing competitiveness with efficient and economical solutions.

Key Features

-

01

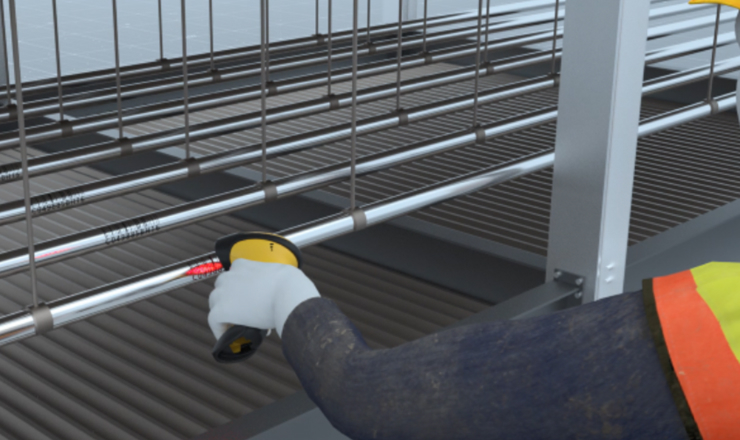

- High-precision 5D piping design-based auto bending system

-

02

- Real-time auto bending simulation with optimal bending path calculation

-

03

- Quality improvement with precision bending, minimizing defect rates

-

04

- Significant reduction in production time and cost

Main Advantages

-

Optimized product design precision using advanced CAD/CAM technology

-

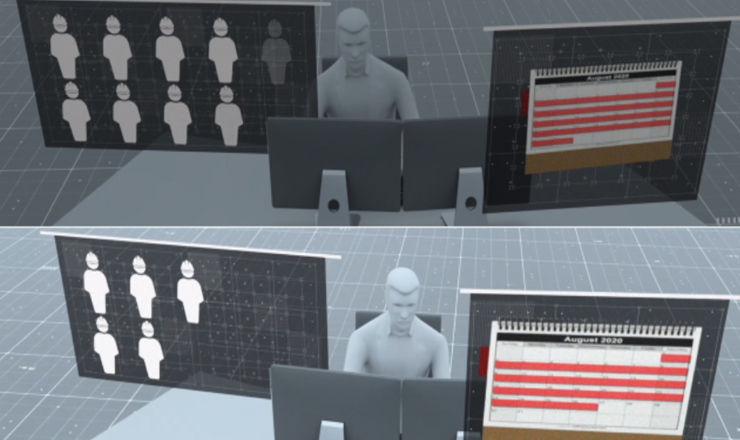

Maximized production efficiency with high-level automation and robotics

-

Real-time data monitoring provides continuous quality control and minimizes defect rates.

-

Competitiveness in high-tech industries through continuous R&D, meeting stringent industry requirements

Perfect harmony of precision and efficiency

lead the future of piping production with our Auto Bending Solution.

-

- Field Safety Incident Reduction

-

Full automation in piping production helps prevent field accidents in compliance with enhanced industrial safety regulations

-

- Enhanced Piping Quality

-

Specialized tasks through separation of construction and production teams improve expertise, while the auto bending system minimizes defect rates and enhances quality.

-

- Cost Reduction and Faster Project Completion

-

Automated blueprint interpretation and piping production reduce costs. The streamlined process, with automated production and quick installation, shortens construction time.