Industrial Digital Twin Platform

- DTDsquare The Core of Industrial Digital Twin, a Hub for Collaboration

- DTDsquare is the central component of the DTDesigner platform. It flawlessly implements every aspect of the industrial site in a digital space through real-time 3D visualization and data synchronization.

play

-

Key Functions

-

- All-round 3D View : 360-degree panoramic virtual environment

- Real-time Data Synchronization : Seamless interoperation with real-time on-site data

- Collaboration-Centered Design : Supports real-time multi-user interaction

- Advanced Editing Tools : Convenient and diverse editing features

-

Applications

-

-

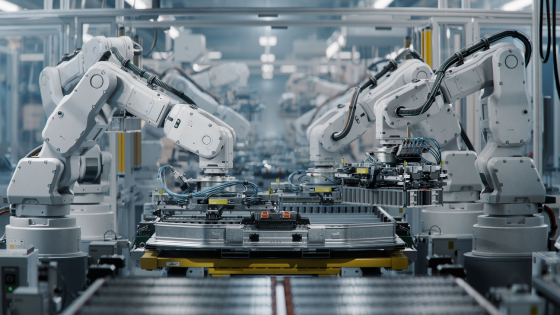

Smart Factory Operations

-

Plant Facility Management

-

Construction Project

Monitoring -

Urban Infrastructure

Planning and Management

-

-

Core Advantages

-

-

- Optimized Decision-Making

- Rapid and accurate decision-making based on real-time data in digital twin space

-

- Cost Savings

- Resource Optimization Through Virtual Simulation

-

- Risk Management

- Proactive detection of risks through predictive analysis and simulation

-

- Enhanced Collaboration

- Real-time collaboration environment unrestricted by space and time

-

-

-

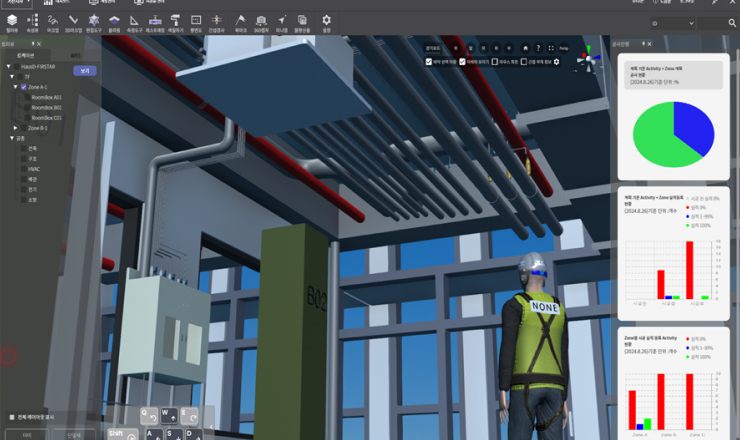

A New Paradigm for Data-Driven Decision-Making,

Perfect Harmony Between Reality and Virtual -

The interface shows a screen displaying the user interface. At the center, a 3D environment recreates the industrial site, allowing operators to perform tasks in a lifelike setting with avatars.

Charts and graphs displaying task progress are automatically updated as input is provided, while the top toolbar provides various functions and analysis tools in an intuitive format. This complete digital twin solution enables users to seamlessly monitor and analyze real-time data in a virtual environment.

-

A New Paradigm for Data-Driven Decision-Making,

-

- Precise Interference Detection for Design and Simulation Review, Preventing Errors in Advance

-

The screen shows the interference detection function. In complex industrial facilities and piping structures, interference checks are essential.

This feature allows errors to be identified in the design stage, preventing issues during construction. Additionally, interference checks can be performed through simulations when planning additional work or maintenance to identify potential issues in advance. This results in reduced construction costs, shortened project timelines, and improved overall project efficiency.

-

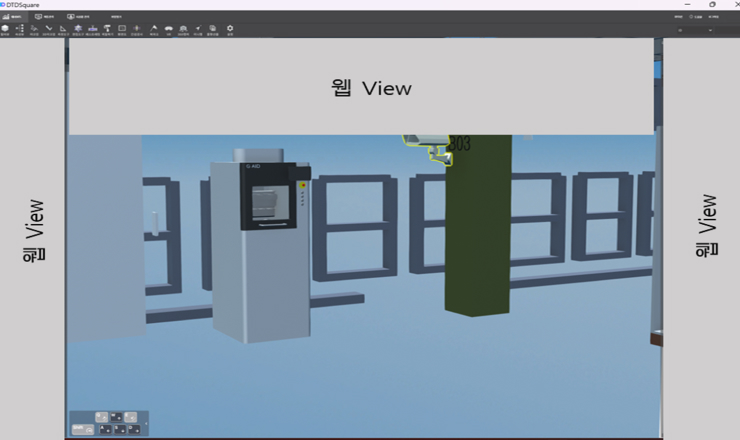

- Editing and Integration with Work Systems

-

Through Web View, existing operational systems are integrated, and newly developed systems are created on a web-based architecture to simplify maintenance and operations for administrators.

The Web View can also be customized as needed.

-

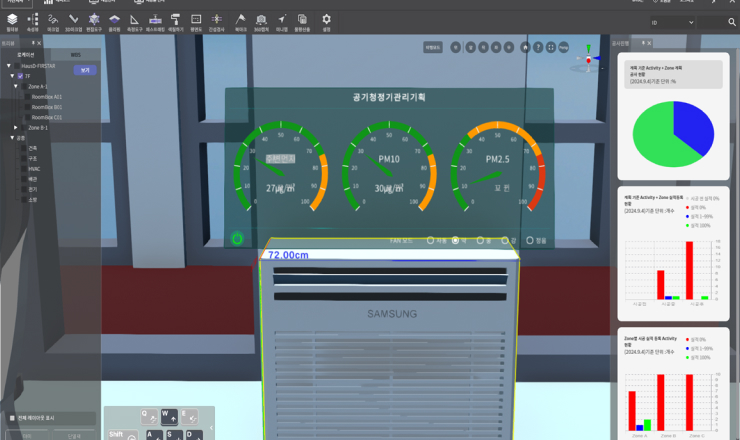

- Real-time Data Integration and Monitoring

-

It enables real-time integration of data collected from various sensors and systems, allowing centralized management within a single platform.Key operational data, including temperature, pressure, speed, and energy consumption, is collected in real-time. This feature aids on-site managers and operators in making faster and more accurate decisions.

Since data is synchronized in real-time, immediate responses can be made when changes or abnormalities occur. This helps reduce operational risks and maintain a more stable environment.