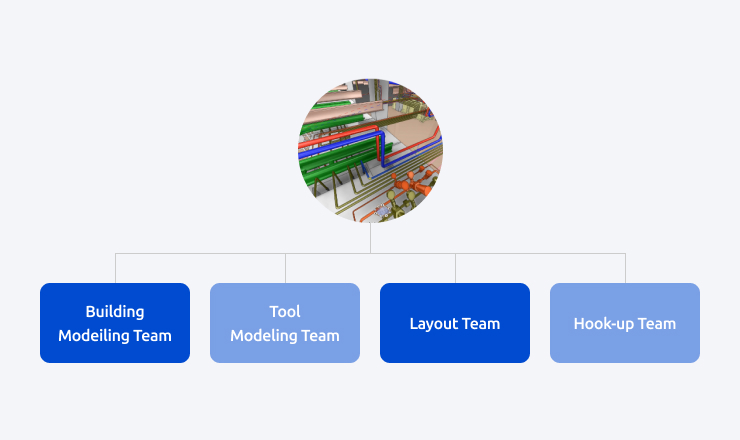

- META FAB We provide an industrial meta platform utilizing BIM (Building Information Modeling) for advanced facility design to address complex industrial challenges.

-

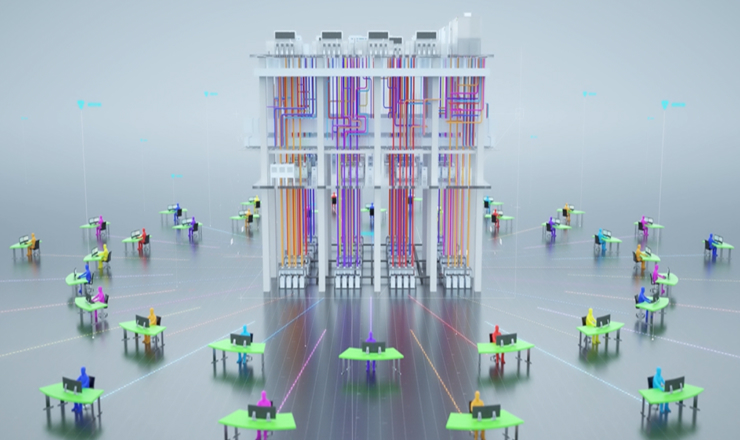

This platform enables users to freely arrange equipment in virtual environments and optimize workspace layouts through simulations, significantly improving on-site safety and productivity.

This innovative approach drives digital transformation across industrial sites, ensuring customer satisfaction through ongoing technology advancements and service improvements.

Key Features

-

01

- Real-time collaborative design minimizes errors and reduces trial and error.

-

02

- BIM-based analysis for optimal process design.

-

03

- Real-time project management to maximize productivity.

Main Advantages

-

Advanced 3D BIM technology allows for equipment placement and workspace optimization in virtual environments.

-

Pioneering digital transformation in industrial sites through continuous technological development.

Experience a new paradigm with the Industrial Meta Platform—share and optimize every stage, from design to construction, in real-time.

-

- Real-Time Design Collaboration in Virtual FAB

-

Due to complex factory conditions, traditional production facility construction often fails to consider the overall FAB environment, leading to frequent rework as each party proceeds based on their own isolated information.

Through the integration of design data with the operating system, the BIM-based META FAB enables real-time monitoring of construction status and prevents design interference and conflicts.

-

- Pre-Construction Digital Twin Implementation

-

With META FAB technology and expertise, ultra-precise design within a 50mm tolerance

is achievable for fine piping in semiconductor FABs.Real-time integration of multiple design datasets allows for interference checks

and enables precise on-site construction through detailed drawings.

-

- All Data from META FAB Utilized Throughout the Factory's Lifecycle

-

The client can secure and retain AS-BUILT drawings. Data produced by META FAB can be linked with P&ID, and data can also be extracted by process.

All data serves as a valuable resource across the entire factory lifecycle,

from hook-up to maintenance.

-

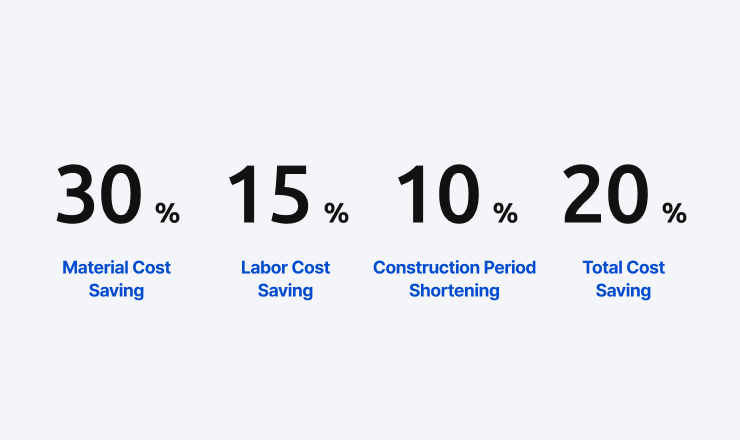

- Substantial Lead Time Reduction from Equipment Installation to Factory Operation

-

Under precise design, unnecessary material waste is prevented,

reducing the average loss rate by over 30%.Virtual simulations before on-site construction reduce setup costs

and shorten construction timelines.

-

- Efficient Operation with META FAB

-

Construction based on real-time design and accurate data minimizes design deviations

and enables clear, easy inspections.Design data can be linked with operational phase drawings or maintained as a digital twin, allowing continuous use throughout the maintenance period.