Industrial Digital Twin Platform

- DTDon A New Dimension of Real-Time Collaboration

-

DTDon is our innovative real-time collaboration solution.

DTDon facilitates efficient collaboration in a 3D model-based virtual environment, free from time and space limitations.

play

-

Key Functions

-

- Real-time 3D Model Sharing and Manipulation

- Support for Multi-party Voice and Video Calls

- Real-time Screen Sharing and Annotation Capabilities

- Instant Information Exchange Between Field and Office

- Accessible From Anywhere With Mobile Device Support

-

Applications

-

-

Construction Site Management and Supervision

-

Manufacturing Process Optimization

-

Remote Maintenance Support

-

Design Review and Approval Process

-

-

Core Advantages

-

-

- Shortened Decision-Making Time

- Rapid decision-making through real-time information sharing

-

- Travel Cost Savings

- Minimizing unnecessary travel through remote collaboration

-

- Enhanced Information Accuracy

- Visual communication prevents misunderstandings

-

- Improved Project Speed

- Immediate feedback and actions

-

-

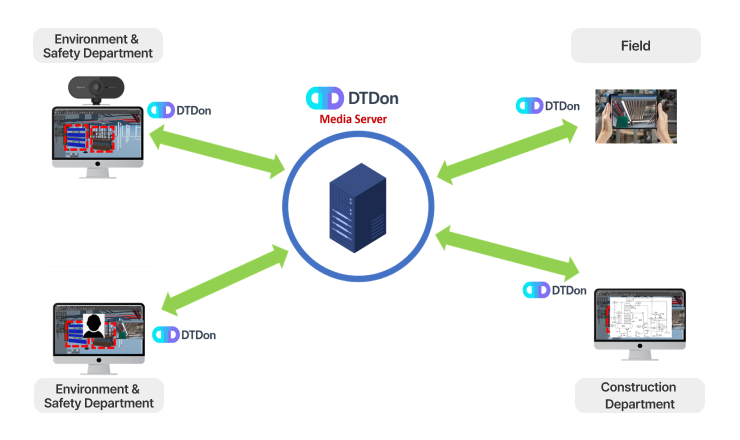

- Real-Time Collaboration Across Departments

-

Multiple users can work simultaneously on the same 3D model, utilizing editing features like 3D markup to document relevant information, allowing for efficient collaboration across different departments.

Additionally, each user can create collaborative chat rooms with stakeholders, inviting them as needed for real-time communication.

-

- Real-Time Communication and Rapid Problem Resolution Between Field and Office

- DTDon enables real-time communication and information transfer between the field and the office. Issues or changes that arise on-site are instantly relayed to the office, where the situation can be monitored in real-time, facilitating prompt response. Through this system, instructions, issue resolution, and feedback on field conditions occur in real-time, greatly enhancing the decision-making speed between field and office. This leads to faster problem resolution and accelerated project progress.

-

- Visual Issue Identification and Collaboration Through 3D Models

- 3D models allow visual confirmation of on-site issues and modifications. On-site problems or changes can be marked up in the model for easy sharing and interpretation at the office. The 3D model visualizes the overall facility status, allowing both field and office to comprehensively understand conditions, significantly aiding collaboration and decision-making.

-

- Avatar System With Real-Time Sharing by Field Workers

- Using the location-sharing feature, the movements of field workers in the factory are represented in real-time by avatars on the office PC. The avatar moves along with each route change, enabling the office to accurately track the location and movements of on-site workers.

-

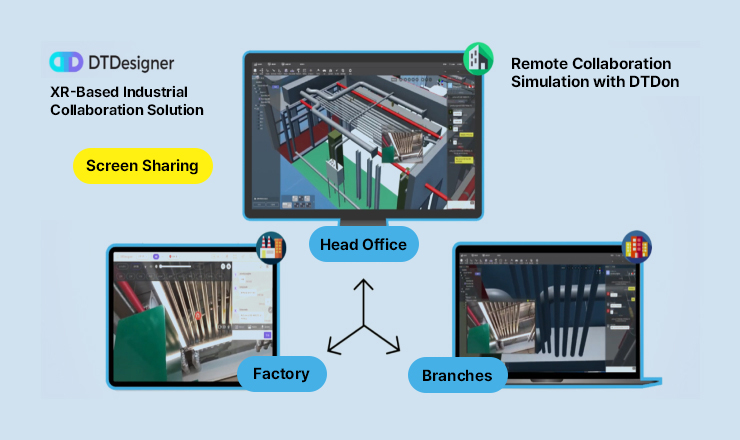

- Real-Time Collaboration via Markup Sharing

- Markups can be applied in real-time to shared screens from a tablet to a PC, with markup content saved and sent to headquarters and branches. These markup files can be viewed consistently across all locations. Selecting the screen’s “markup move” button automatically navigates to the marked location. This simplifies visual collaboration across headquarters, factory, and branches, enabling quicker identification and resolution of on-site issues.