Industrial HVAC System (Heating, Ventilation, Air Conditioning)

- Automatic Control System Core of Smart HVAC

-

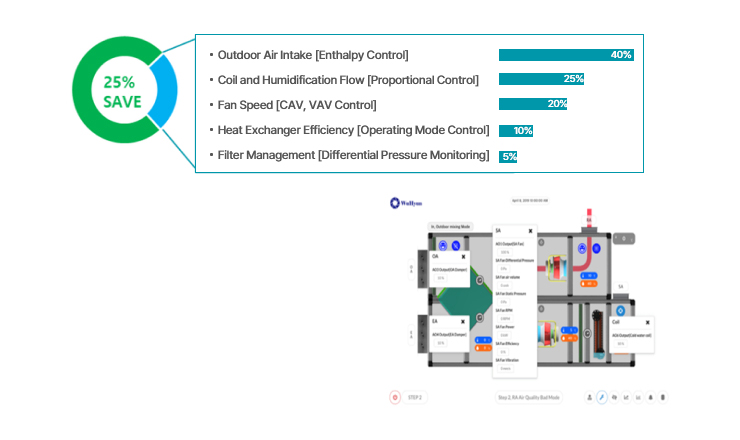

Our industrial controllers enable up to 25% energy savings through an advanced control system that manages enthalpy, proportional settings, fan speed, operating modes, and differential pressure.

Additionally, an intuitive display monitor supports both on-site and remote control, offering detailed operational statistics, including energy usage.

By leveraging automatic control data, predictive HVAC becomes feasible, setting the standard for smart HVAC solutions.

-

Key Functions

-

- Maintain optimal operating conditions via data collection and analysis

- 5 Core Controls: Enthalpy Control, Proportional Control, Fan Speed Control, Operating Mode Control, and Differential Pressure Control

-

Applications

-

-

Air Handling Units

-

Fans

-

HVAC for Smart Farms

-

Fan Control Sysytem

(FCM)

-

-

Core Advantages

-

-

- Realization of Predictive Operation

-

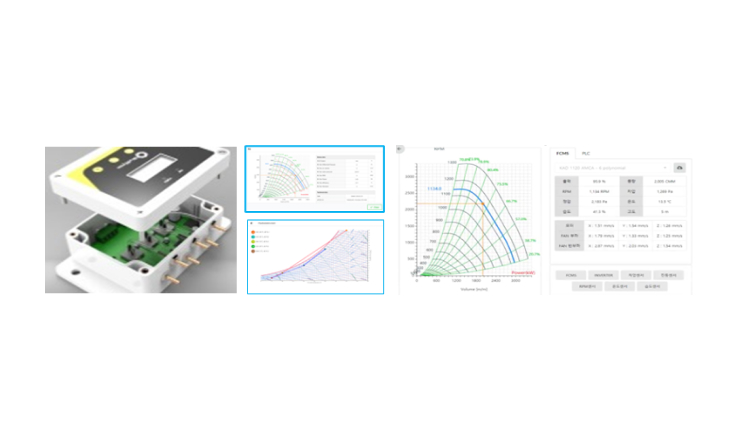

- Real-time Data Collection for Static Pressure, Power, Efficiency, and RPM (FCM)

-

- Visualized Monitoring Display

-

-

- HVAC Equipment Control System (Smart Farm HVAC Control)

-

This system collects and analyzes all operational data from HVAC units to maintain optimal operating conditions.

Our proprietary advanced fan control technology enables predictive operation, achieving up to 25% energy savings.

-

- Fan Control System (FCM)

- We developed the world’s first system (FCM) for real-time data collection and control of blower airflow, system static pressure, power, efficiency, and RPM during equipment operation. This precise, real-time data collection enhances system stability and maximizes efficiency. Information is also visualized on a monitor for improved user accessibility and convenience.

-

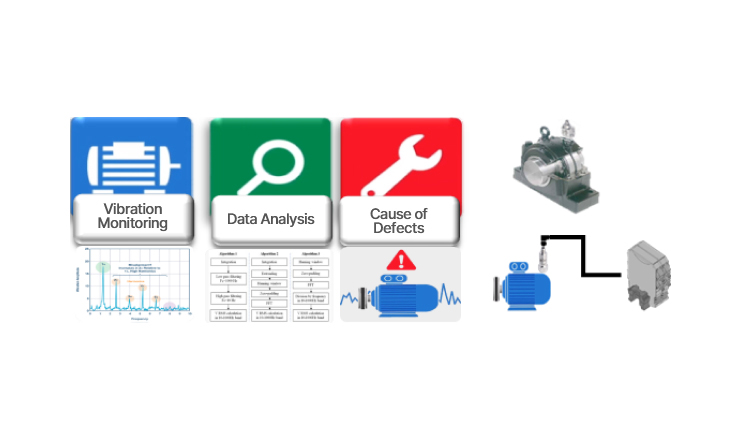

- Vibration Monitoring Technology (VMT)

- Industries such as power plants, semiconductor manufacturing, and chemical processing require blowers that operate continuously, necessitating periodic vibration monitoring for safety. Our VMT monitors real-time blower operation and captures three-axis acceleration vibration values, enabling quick identification of vibration sources. VMT is especially optimized for blowers, offering excellent cost-efficiency in this application.